IBF3001 & IBR3001 Liquid Waste Soil Injector

The liquid waste soil injector can be delivered in 3 formats

- 1. Front Primary Ripper Bar with Injection Plumbing – Basic setup.

- 2. Rear Tanker mounted Injector bar – Cultivated soil or shallow injection only

- 3. Front Primary Ripper Bar + Rear Injection Bar – Ultimate setup for deep soil liquid injection meeting EPA regulations

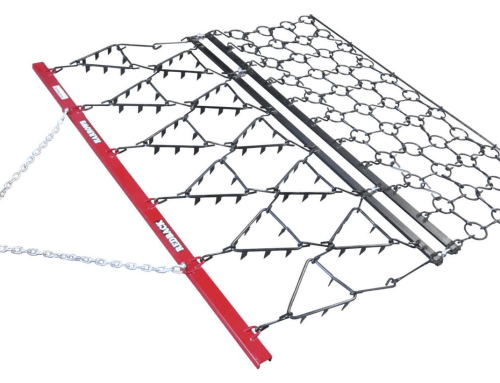

- The front primary bar is tractor 3PL mounted ripper toolbar. This bar carries the vacuum tanker by way of a unique drawbar that transfers weight forward onto the tractor rear axle while still maintaining a tight turning angle. This primary bar is fitted with 4 shear pin protected tynes to allow for penetration and depth in virgin soils

- The secondary bar is mounted behind the vacuum tanker on a 4PL that utilizes the existing tanker mounts. A manifold directs the liquid behind 4 x heavy spring protected chisel plough

- A hydraulic motor is fitted to the vac pump for superior control and pump protection

- The 4 tynes are staggered to rip offset to the wheel tracks of the tractor and vac tanker

- The plumbing is all Cam-locked for easy maintenance.

- The toolbars are very heavy duty and hot dip galvanized for a long life.

Or Call Us : 0428 389 531

To design a liquid waste soil injector that:

- Rips virgin soils up to 400mm

- Is capable of injecting viscous waste liquids reliably, safely and cleanly to a depth that meets EPA requirements

- Utilises the tractor draft control for the primary ripping of compacted soil while minimising stresses being placed on the vac tanker

- Injects the liquid behind the vacuum tanker to eliminate “squelching”

- Allows for multiple passes while minimizing the risk of bogging

- Does not require a macerator to be used

- Is compatible with various brands of vacuum tankers

- The 2 toolbar combined with unique drawbar design focuses the majority of draft load on the tractor, not through the tanker

- The injected soil is not driven over, minimizing the risk of squelching and therefore odour

- Depth of injection is maintained to meet all EPA requirements

- Clean injection of all liquids including Treated Grease Trap, Food Wastes, and Effluent.

- No centrifugal pump or macerator minimize blockages.

- Large pipe sizes, Cam-locked fittings, and in-built dump/cleaning caps minimize blockages and allow easy maintenance.

- Hydraulic driven pump allows independent engine rpm’s to be utilized. This allows the vac tanker to be loaded at idle, while higher/varying rpm’s can be used for injecting. The pressure controlled flow valve provides extra vac pump protection, while the lack of a PTO shaft improves safety.

- Simple, reliable, productive and cost effective

- Designed, engineered and fabricated for Australian farmers right here in Australia

Specifications |

IBF – Front Injector Bar |

|---|---|

| Working Width | 3000-4000mm |

| Transport Width | 3000-4200mm |

| Power Requirements | Dependent on Vacuum tanker capacity – minimum 150hp for a 10 000 litre tanker and 2 injector bars (180hp ideal). Hydraulic trailer braking is necessary |

| Toolbar | 150 x 150 x 9mm RHS or 200x200x12.7mm |

| Tynes | 4 x 650mm height |

| Tyne Spacing | Adjustable around wheel track |

| Tyne Breakout | Shear pin – 5 Tonne.

Hydra-Max – up to 8Tonne with hydraulic breakout and reset |

| Shear pin | Magazine styled, tool-less quick replace |

| Tyne point | Knock-on points with various widths available, fitted with shin guards |

| Mount | Category 3. The IBF3001 can be used as a stand-alone deep ripper |

| Tanker Drawbar | Foward hinges, rear pivot |

| Finish | Hot dip galvanized/2-pac enamel |

| Other | Parking stands |

Specifications |

IBR3001 – Rear Injector Bar |

|---|---|

| Working Width | 3000mm |

| Transport Width | 3020mm |

| Toolbar | 100x100x6mm RHS |

| Tynes | 4 x RFM NT600 coil spring tynes

4 x Hydra-chisel 1500kg breakout auto-rest tynes |

| Tyne Spacing | Adjustable around wheel track |

| Breakout | 300-1500kg |

| Tyne Point | Ag-point Slimwedge adapter + various knock-on chisel points |

| Mount | Category 3 3PL + 4PL to suit tanker mounts The IBR3001 can be used as a stand-alone liquid injector |

| Tanker Piping | 150mm Cam-locked fittings |

| Supply Piping | 5m x 100mm Cam-locked hose |

| Manifold | 150mm manifold – to suit 150mm hyd knive gate, fitted with dump caps for easy cleaning, 4 x 75mm outlets |

| Injection Piping | 75mm Cam-locked hose + injector tubes |

| Hydraulics | Includes injector bar lift hoses and knive valve extension hose kits |

| Hydraulic Requirements | 1 x double acting (vacuum pump control valve) 1 x single acting + 1 x free return (vacuum pump motor) 1 x single acting with float detent (IBR3000-1 lift) 1 x single acting (knife valve) |

| Depth Gauge Wheels | 2 x 155R13 galvanised rim wheel assemblies |

| Finish | Hot dip galvanized / 2-pac enamel |

| Other | Parking stands |

| Options | As per customer requirements |

Specifications |

IBH – Hydraulic Vac Pump Kit |

|---|---|

| Hydraulic Motor | 100cc Orbital motor |

| Pump Adapter | 6 pline flexible disc coupler |

| Control Valve | Variable flowrate pressure control valve |

| Other | Clamp-on mount kit, Hydraulic hose kit |

| Tyne Spacing | Adjustable around wheel track |