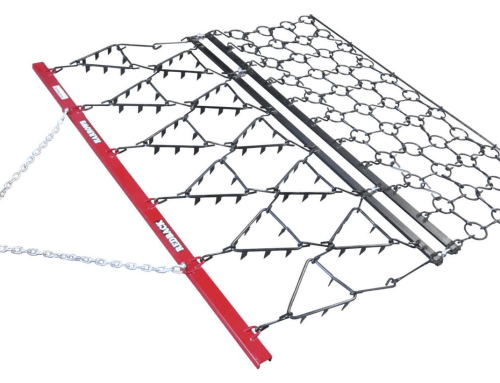

Cruiser Hay and Silage Bale Feeder

After watching farmers wasting precious hay during this drought by either paddock feeding or using sub-standard hay feeders, Doyle Ag & Fabrication tested various designs and have come up with the “Cruiser” of hay and silage feeders.

Contact the team at Doyle Ag & Fabrication to learn more about the Bale Feeder, all our products are Australian made and built to last.

Or Call Us : 0428 389 531

- Value – the best designed and best built bale feeder in Australia

- Design – a “V”rack holds the feed up and a trough catches any leaf, while the slanted bars limit cattle pulling feed out and dropping on the ground.

- Efficient – reduces up to 80% of feed losses

- Economical

- Can pay for itself in as little as 115 bales or 57 days

- Over 500 bales, will not only pay for itself, but save up to another $13,000 on feed losses – Not a bad return on investment!!

- Very Heavy Duty – it weighs over 450kg. Built to take a beating by any farm-hand, father or fuming bull, load up with as much silage as you can fit.

- Durable – The only hot dip galvanized frame on the market will last 2-3 times that of a DuraGal feeder with no uncoated welds or internals to corrode, no tek-screws to rattle out, and no spot welded sheeting to crack off

- Safe – No tek-screws, bolts or rivets for cows to eat

- Serviceable – quick-fit galvanized trough sheets are quickly and easily replaceable with no screwing or welding required – saves everyone who has left a bale to rot or a lick block in a feeder

- Mobile – can be pallet forked or skidded

- Large – feeds 22 head at a time and fits 2 x round bales

- Transportable – stack 2 x high to save on freight costs

Specifications |

Cruiser Hay and Silage Feeder |

|---|---|

| Length | 3000mm |

| Width | 1780mm |

| Height | 1550mm |

| Feed trough height | 500mm |

| Lifting Points | Pallet fork tubes @850mm centres |

| Chassis | Heavy RHS, 100PFC and angle |

| Trough | Quick fit galvanized sheeting, no fasteners required |

| Finish | Hot Dip Galvanised |